There are so many demolition machines on the market. It doesn’t matter if you are a big demolition company or if you are managing your project. If you look through the lens of these three factors, you’ll make the right decision and be better at picking the machine that fits your job perfectly.

Choosing the right demolition machines for your project involves assessing key factors like the machine’s capabilities, attachments, and budget. In this guide, we’ll explore what to look for when buying demolition machines, ensuring your purchase aligns with your specific requirements.

Now that we have the foundation built, let’s dig into what demolition machines are and how they work. So, you can start purchasing.

Table of Contents

Toggle1,What is a Demolition Machines and How Does It Work?

Demolition equipment is heavy-duty machinery built specifically to tear down and dismantle structures. These big boys are built for the harsh demands of demolition work, whether that’s tearing down buildings, moving debris or crushing concrete. Their power and versatility make it the kind of equipment you can’t live without if you’re working on big projects.

The way demolition machines work is by using a combination of force, hydraulics, and specific attachments to tear down buildings. For example, you can take an excavator and fit it with a hydraulic hammer or a shear, to cut through something tough like concrete or steel.

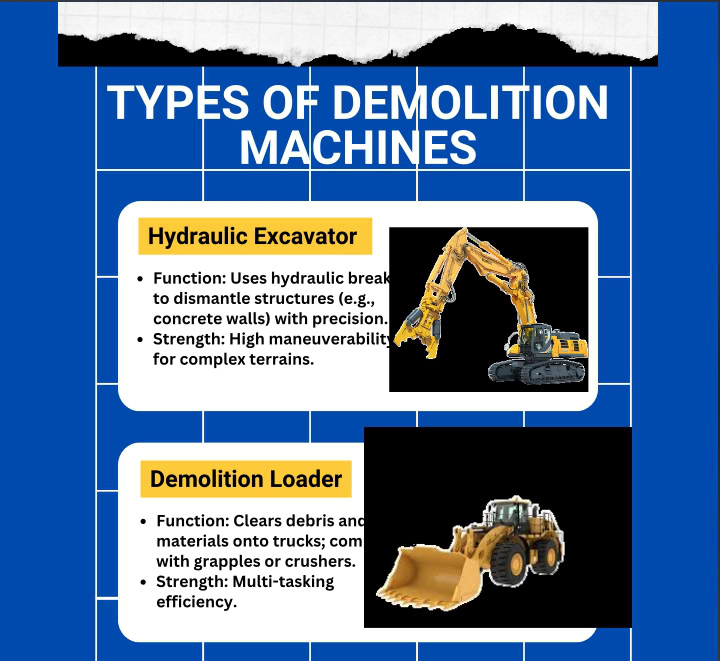

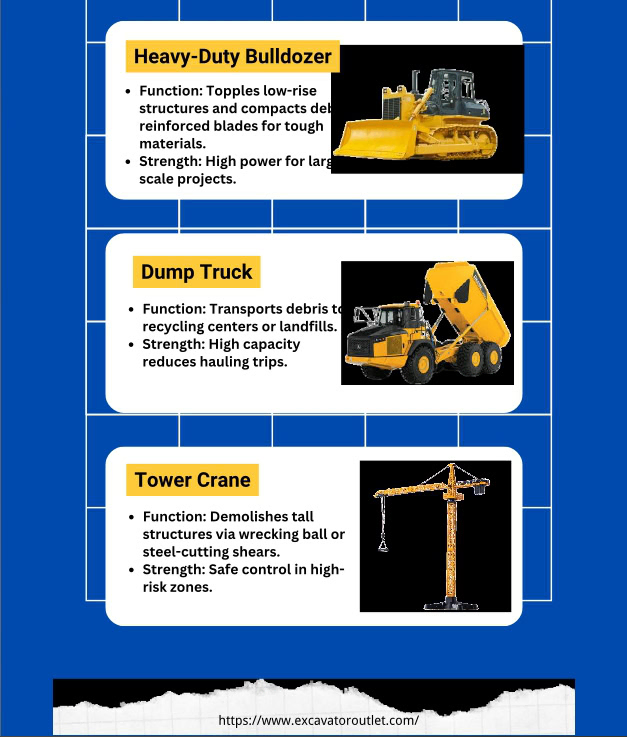

Types of Demolition Machines:

| Type of Machine | Primary Use | Common Attachments |

| Escavatori | Heavy lifting, debris removal | Hydraulic hammers, shears, crushers |

| Caricatori | Material handling | Buckets, forks, grapples |

| Skid Steer Loaders | Compact workspaces | Buckets, augers, compactors |

| Hydraulic Breakers | Breaking concrete, rocks | Various sizes of breakers |

| Demolition Robots | Precision demolition | Specialized tools for precision cutting |

These machines work in different ways depending on what you need to do. For example, you can take an excavator and put a hydraulic hammer on it to go break concrete. Loaders are used to help when moving debris, while specialized demolition robots are used for tiny tasks, like removing pieces of a building that require a delicate hand.

2,Key Features to Look for When Buying a Demolition Excavator

When you are looking to buy or rent a demolition excavator, it’s extremely important that you focus on certain features that will help when doing a demo job, whether it’s a small job or something large like tearing down an entire large office building. Understanding the features that matter and which ones can help you out when choosing a machine is important.

You should focus on the lifting capacity of the machine, the hydraulic system, and what attachments the machine can handle. The better the hydraulic system, the more power you can apply to a specific area. Also, a heavy lifting capacity sure doesn’t hurt when it comes to moving stuff.

Important Features to Consider:

| Feature | Description | Why It’s Important |

| Hydraulic System | Powers attachments and enhances machine mobility | Ensures smooth operation of attachments like hammers and shears |

| Lifting Capacity | Ability to carry heavy materials | Prevents overloading and improves safety |

| Attachments Compatibility | Ability to switch between different attachments | Increases versatility for various demolition tasks |

| Fuel Efficiency | Machine’s fuel consumption rate | Reduces operating costs for large-scale projects |

The top end demolition excavators are ones that you can easily move from job to job by switching out the attachment. Look for an excavator that can take various tools like a hydraulic breaker, a shear or a crusher.

3,How to Evaluate the Quality and Reliability of Demolition Machines

If you need demolition equipment, especially for a big job, you won’t go wrong if you focus on buying a reliable, good piece of equipment. You want the machines to last and perform, job after job after job.

Have an idea of the quality of the machine. See what the manufacturer’s reputation is as far as what current or past user reviews have said about the machine. Look and see if it has any kind of warranty or certification available. The more reliable a machine, the less downtime you have and the fewer repair bills you have cropping up.

How to Assess Reliability and Quality:

| Aspect | What to Look For | Why It Matters |

| Brand Reputation | Look for well-known brands like CAT, Komatsu, Sany | Trusted brands offer high quality and after-sales service |

| User Reviews | Check feedback on performance and longevity | Real-world experiences can provide insights into machine reliability |

| Certification and Warranty | Ensure the machine is certified and comes with a warranty | Guarantees machine quality and protects your investment |

But, typically the most reliable machines come from big name manufacturers in the construction industry space: CAT, Komatsu, Sany, those types of guys. These huge machines are popular for demolition because they know from years and years of use those suckers stand up and keep getting back up off the mat.

4,What Machinery is Used for Demolition?

Demolition happens with all kinds of equipment, each doing a specific part of the job. Know which machine does what will help when you have to make the big decision about what piece of demolition equipment to buy.

Some demolition machinery includes excavators, hydraulic hammers or breakers, and skid steer loaders, just to name a few. Each type of machine does something very specialized on the job from breaking down large structures to clearing away the debris.

Common Machines for Demolition:

| Machine Type | Primary Use | Recommended For |

| Escavatori | Heavy lifting and breaking structures | Large demolition projects |

| Hydraulic Breakers | Breaking concrete and rock | Large-scale concrete demolition |

| Skid-Steer Loaders | Clearing debris and site preparation | Smaller demolition sites or tight spaces |

Depending on the scale and type of demolition you have, you may need a combination of the machines. A hydraulic hammer or hydraulic breaker is useful for breaking up concrete. A skid steer loader works best in tight spaces where a bigger machine can’t squeeze in to operate.

5,What is the Best Machine for Demolition?

The “best” machine to use on a demolition project varies, depending on the size and scale of the project, what you intend to tear down, and how fine your cut or break has to be. While the best machine is subjective, from an efficiency, versatility, and durability standpoint, some machines are head and shoulders above the rest.

For big-scale or straight demolition, the best unit is usually a high-powered excavator with hydraulic attachments. For smaller, more precise demolition, you might use a demolition robot or a skid steer loader.

Best Machines for Different Types of Demolition:

| Project Type | Best Machine | Reason Why |

| Large-Scale Demolition | Excavator with hydraulic breaker attachment | High lifting capacity and versatility |

| Precision Demolition | Demolition Robot | Offers precision in handling delicate structures |

| Site Clearance | Skid-Steer Loader | Perfect for tight spaces and debris removal |

The best demolition machines is whatever works best for your particular situation. For big demolition, you usually want a high-powered excavator with hydraulic attachments. For more precise demolition or if you’re working in a smaller area, a demolition robot or skid steer loader might be the right way to go.

6,What Are the Three Types of Demolition?

Demolition is a very broad term, and you can break it down into three main categories: mechanical demolition, explosive demolition, and manual demolition. Each type has its place depending on what kind of structure you’re knocking down and the project requirements.

Mechanical demolition includes heavy machinery with hydraulic attachments, such as an excavator, loader, or bulldozer. Explosive demolition uses explosives in a controlled way to bring down buildings. Manual demolition involves a bunch of people beating a building down bit by bit.

The Three Types of Demolition:

| Type of Demolition | Primary Machines Used | Common Applications |

| Mechanical Demolition | Excavators, bulldozers, hydraulic shears | Large buildings, warehouses |

| Explosive Demolition | Explosives, detonators, demolition robots | High-rise buildings, bridges |

| Manual Demolition | Sledgehammers, drills, hand tools | Small structures, interior demolition |

Everything we just talked about will help you choose the best demolition equipment, which will help you get out of that “deer in the headlights” feeling you might have due to all the choices. The trick is to understand exactly what you need (e.g., what are you tearing down? what is it made out of? do you need finesse to knock it down or brute force?).

7,What are the Costs Involved in Buying Demolition Machines?

The cost to purchase one of these machines can vary significantly depending on the brand, model, age, and hours of use. When you’re getting ready to make a purchase, always remember it’s not just the cost of the machine you need to think about. It also includes the long-term costs: maintenance, repair, and downtime.

While it’s the price of the machine, remember, you have to get it shipped to you. And, you have to learn to run it. Occasionally, you have to hire somebody to help you learn to run it. So always calculate the total cost of the machine, not just the out-the-door price.

Cost Breakdown of Demolition Machines:

| Cost Element | Explanation | Estimated Cost |

| Machine Price | Purchase price for new or used machines | $50,000 – $300,000+ |

| Shipping | Cost to ship the machine from the supplier | $5,000 – $10,000 |

| Maintenance | Ongoing maintenance and repair costs | $1,000 – $5,000/year |

| Training | Cost to train operators on machine usage | $500 – $2,000 |

The initial cost of equipment like this stuff can be expensive. While it’s a high-ticket item up front, these machines pay for themselves many times over if you use them properly. Just don’t forget that when deciding to buy one.

8,How to Ensure Timely Delivery and After-Sales Support?

You need to make sure that thing shows up on time. You need to be sure that you have the people to support it when it shows up because it’s not going to do you any good if you have it sitting on the job and can’t use it. Make sure you get it on the job and start tearing stuff up.

They should also be able to tell you when the machines would come in and supply you with parts so that in four to five days, they could have on hands what they would need to fix the machine to get you back working. A good supplier will keep you working when you need to be working.

Ensuring Timely Delivery and Support:

| Factor | What to Look For | Why It’s Important |

| Delivery Schedule | Clear timelines for shipping and arrival | Avoid delays in project start |

| After-Sales Support | Access to maintenance, training, and parts | Ensures machine longevity and performance |

Buying demolition machines isn’t just about the purchase price or the machine itself. It’s also about the delivery time and the support after the sale. These are all important reasons to make sure you choose the right supplier for your demolition machine.

9,Emerging Trends in Demolition Machines and How to Choose the Right Supplier for Your Project

The demolition machinery industry is going through a lot of technological changes. Everything from automating machinery and making it robotic to green machinery. So if you want to have a successful project, make sure you keep up with these trends and do business with someone who can help you bring these trends to your project when you need them.

The world’s moving into smarter and faster demolition machines. They’re moving from automation to robotic demolition to green machinery. And again, a good supplier can make sure it gets to your job when you need it.

Emerging Trends in Demolition Machines:

| Trend | Description | Impact on Demolition Projects |

| Automation and Robotics | Use of automated machinery and robots in demolition | Increases efficiency, reduces labor costs, and improves safety |

| Green Demolition Machines | Use of eco-friendly machinery that reduces carbon footprint | Meets environmental standards and boosts the project’s green credentials |

| Remote Operation | Machines operated remotely for safety and precision | Improves safety, minimizes operator risk, and allows work in hazardous conditions |

| Smart Machines with IoT Capabilities | Integration of sensors and IoT technology for predictive maintenance | Reduces downtime and enhances machine lifespan through data-driven insights |

Why Supplier Trust is Crucial:

| Factor | What to Consider | Why It’s Crucial |

| Brand Reputation | Look for suppliers with a proven track record and positive customer reviews | Ensures reliability, quality products, and long-term partnerships |

| After-Sales Support | Availability of spare parts, repair services, and training for operators | Reduces downtime, improves machine performance, and extends product lifespan |

| Delivery and Logistics | Timely and reliable delivery schedules | Ensures machines arrive on time, reducing delays and keeping projects on track |

Summary:

To choose the right demolition machine, think about the needs of your project. When considering which aircraft carrier to buy, think about what you need it to do. Consider the features of the machine, the price of the machine, and the after-sales support. By looking at those three factors, you’ll make a great choice and get the machine that’s the perfect fit for your demolition project. Contact with us for more information!

Follow us on YouTube.